If you’re sticking to your in-house print shop production model, the cost impacts may be providing your competitors a significant advantage. In the face of declining print volumes, the fixed costs of your shop are bound to drive up unit costs. Combined with capital expenditures for new capabilities or aging equipment replacement, it becomes difficult to justify the continued in-house operations.

Industry and global trends are driving communications and customer engagements in a variety of channels and modes previously dominated by printed communications. This digitization of your customer experience and brand presence has serious implications for your near-term and longer term operating cost models. In the past five years, digital communications have helped companies save millions of dollars annually through reduction in print and postage spend. Many large corporations have embraced this trend and have made the decision to get out of the in-house print shop business. Yet, many are hanging on to their in-plant services, perhaps, to their own detriment.

Surely, it is a tough decision to outsource a significant operation within your business with a $10M to $20M annual spend. Concerns for employee welfare are paramount. Other concerns include quality of output, internal business services delivery, timeliness of production delivery and regulatory compliance. A well-planned approach to outsourcing can and must address each of these areas. (We’ll address the approach in future posts.)

Here are top reasons to consider outsourcing your print shop:

1. The trend towards increasing digital forms of communication and reduced print volume

2. Reducing total cost of print and delivery

3. Leveraging emerging technologies that may not exist within your shop

4. Focusing human and monetary capital on your core business and competencies

5. Achieving a variable cost model that optimizes spend across various types of print

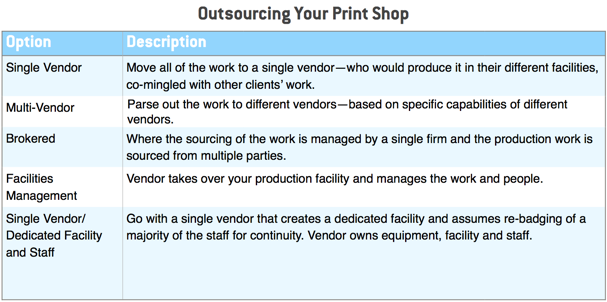

Once you begin the outsourcing investigation, understand that multiple options exist for sourcing your print production and delivery services. These options are not a one-size-fits-all, so thorough evaluation is required. Often, a combination of service and vendor options is appropriate. Look at the types of work performed in your shop and determine the appropriate model for each. Consider the high-level table of options below:

Each of the options above has a right fit and place within a solution set. The difficulty is in determining the right option or options based on your firm’s needs and business requirements.

Make no mistake. This effort is a large and time-consuming process, but one that can yield savings of 10% to 15% of production costs once the transition is complete. Expect the evaluation and due diligence to take in the neighborhood of six to 12 months and the work transition to take nine to 18 months. Of course, these timelines vary based on the size and complexity of each organization.

The bottom line is that print production and delivery has become commodity-based, with continued volume reductions expected. Your competitors are leveraging variable cost models for commodity services. Why aren’t you?

Tom Roberts has more than 20 years of experience in business technology. He serves as a principal consultant at Doculabs, where he develops strategic plans to help organizations use ECM technologies to achieve their business goals. Follow him on Twitter @tomroberts72 or email troberts@doculabs.com. This content originally appeared on the Doculabs blog. For more information, visit www.doculabs.com/docublog-news/blog.